Vented Caps

Scope of application

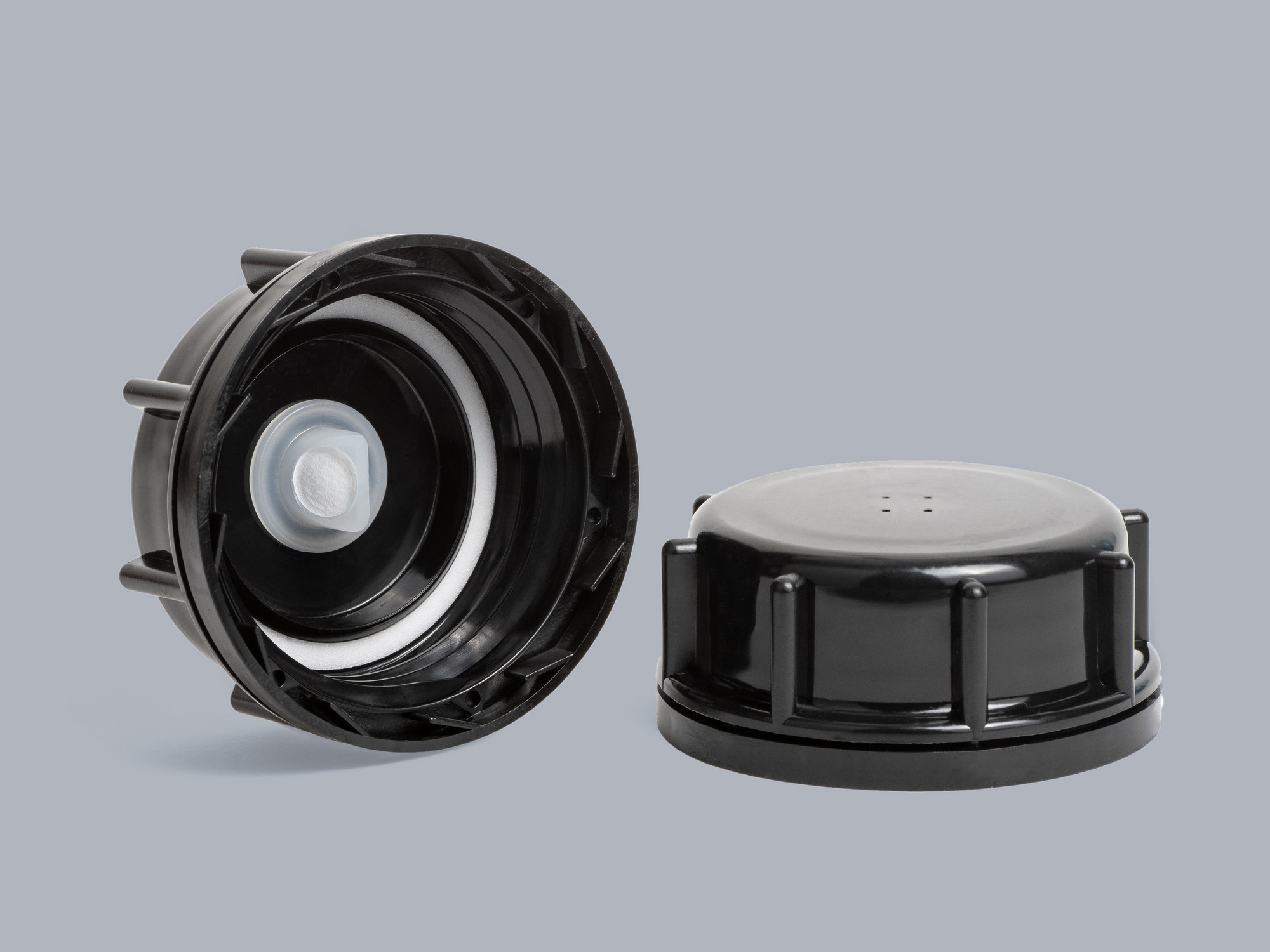

Our unique FLUXX® Vented Caps are equipped with the SAVE-System and are available for common thread sizes with DIN 45, 51 and 61. For the venting system we are using high-quality membranes, which enable a continuous pressure compensation with gaseous liquids, to prevent containers from swelling and collapsing. The membranes are hydrophobic as well as oleophobic, and as a result, they are not saturated even by liquids with a low surface tension.

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

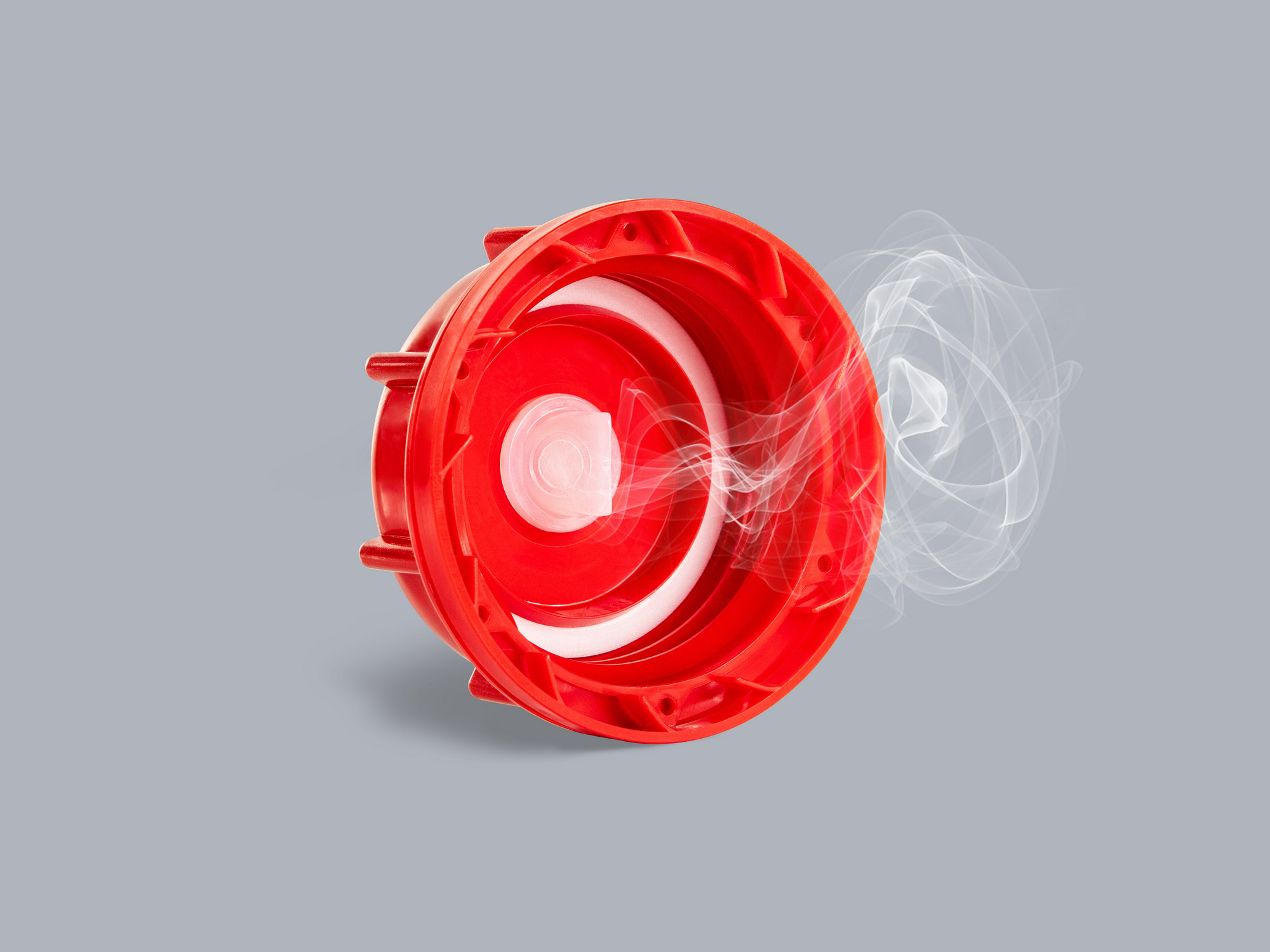

NEW: FLUXX® Vented Caps HF

You need a venting solution with ultra-high airflow?

The search is over – We have the appropriate products for you!

Our new FLUXX® product – the KSE SAVE OV HF (High-Flow) with DIN 45, DIN 51 and DIN 61 – is guaranteed to impress with ultra-high airflow performance. This product solution enables the optimal venting of various containers in heavy pressure situations with highly outgassing substances.

The KSE SAVE OV HF is also equipped with our unique SAVE (SAfety VEnt) system as well as compliant to food industry standards.

Additional information

Application examples

- Liquid food

- Hazardous substances and other chemicals

- Agrochemicals

- Cleaners

- Hygiene and care products

Benefits (X-tra)

- Continuous pressure compensation

- Prevent containers from swelling and collapsing

- Reliable protection against leaks

- Drip-off edge for a rapid re-ventilation after contact with liquids

- Ready to use – venting component combined with the cap

- Declaration of food conformity

SAVE Venting System

The SAVE (SAfety VEnt) has a wedge-like design and the membrane is welded on at a 60° angle. This enables the liquids to drain off immediately, leaving the membrane unobstructed and air permeable. In addition, no splash protection is needed as the liquid flows past the beveled membrane, should a canister fall over, rather than hitting it head-on.

Mode of operation

With FLUXX®

Venting System

Without

venting system

Colors

Black

Red

White

Blue

Yellow

Green

Materials

| Cap: | Polyethylene (PE) | |

|---|---|---|

| SAVE: | Polyethylene (PE) | |

| Membrane: Backing: | Polytetrafluorethylene (PTFE) Polypropylene (PP) | |

| Sealing Ring: | Expanded Polyethylene (EPE) | |

Customizations (especially alternative membranes) upon request.

Suitability for hazardous goods

Because of the construction and performance values, our FLUXX® Vented Caps can meet all requirements for authorization with various containers – especially in accordance with the test specifications set forth in the ADR regulations. As a standard feature, the caps are equipped with a molded on tamper-evidence ring as well as an EPE sealing ring.

Declaration of food conformity

Our listed products comply with regulations EU no. 10/2011, EC no. 1935/2004, LFGB, FDA as well as Mercosur and are fit for human consumption under the food law as well as from a physiological point of view – inspected and approved by certified testing institutes.

Chemical resistance

Our products achieve a high chemical resistance to many liquids. However, we cannot guarantee comprehensive chemical resistance of specific applications. Therefore, we recommend individual testing of customer applications prior to use – with the support of our experts.